Research Symposium

25th annual Undergraduate Research Symposium, April 1, 2025

Alex den Boggende Poster Session 2: 10:45 am - 11:45 am/ Poster #6

BIO

Alex den Boggende is a Presidential Scholar at Florida State University hailing from Bradenton Florida. As an Industrial Engineering major, his research interests include nanomaterial impact testing, supply chain logistics, and sustainable fuel sources. Alex is currently involved in several organizations around campus including the Society for the Advancement of Manufacturing and Process Engineering, Society of Manufacturing Engineers, and the Institute of Industrial and Systems Engineers. He is on track to graduate with a Bachelors degree in 2028, but plans to stay and continue his academic career at Florida State to earn a Masters in Industrial Engineering.

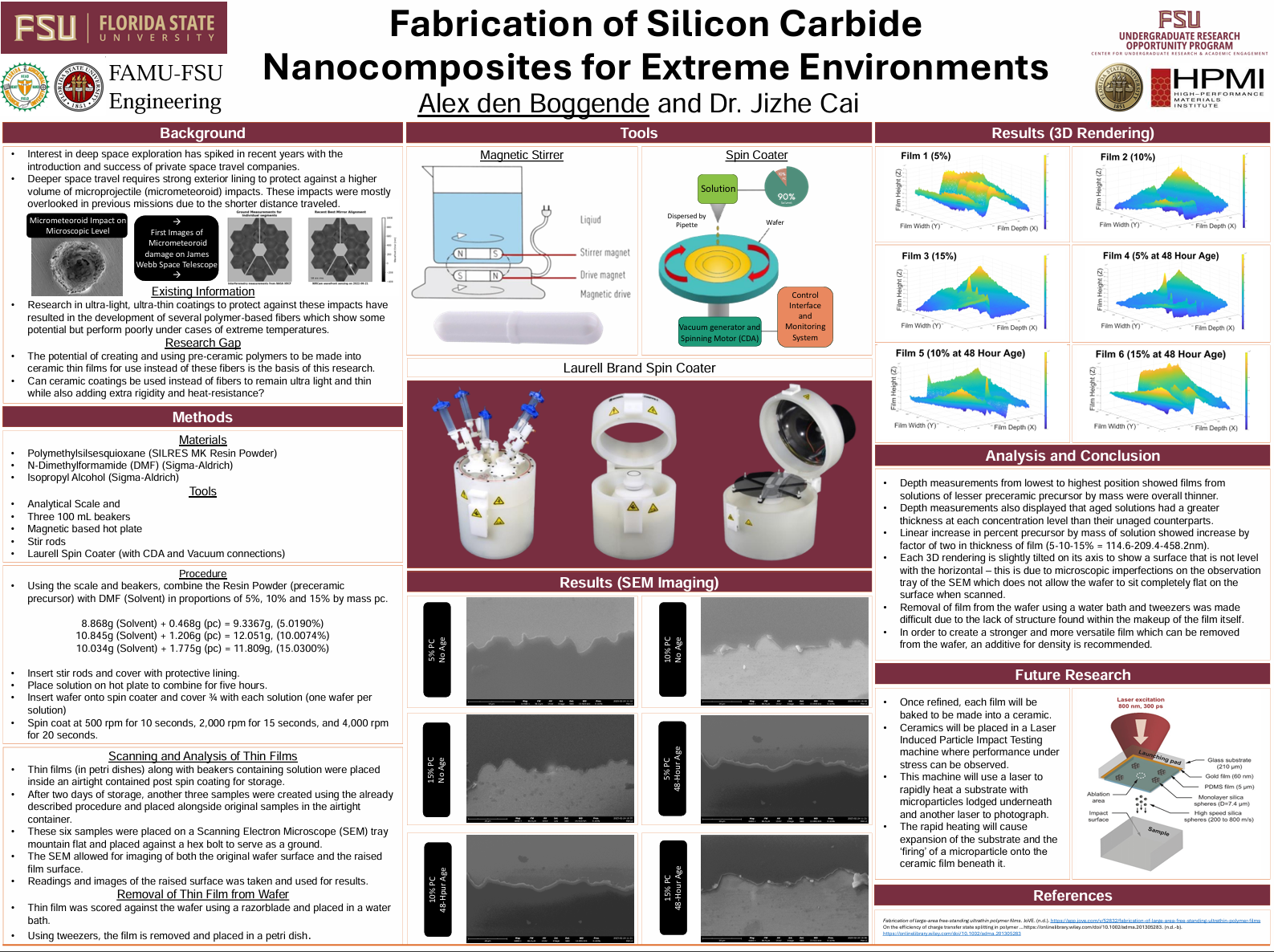

Fabrication of Silicon Carbide Nanocomposites for Extreme Environments

Authors: Alex den Boggende, Jizhe CaiStudent Major: Industrial Engineering

Mentor: Jizhe Cai

Mentor's Department: Department of Industrial and Systems Engineering / Department of Mechanical Engineering Mentor's College: FAMU-FSU College of Engineering Co-Presenters: N/A

Abstract

As space agencies expand their horizons to push deeper into our solar system, the vehicles themselves, and more importantly their exterior lining must become more sophisticated to microprojectile impacts such as space dust moving at high speeds. Within the field of polymer-based materials research, it has been determined that thinner materials (<100nm) results in a different and stronger polymer chain structure which could be vital to safeguarding spacecrafts in their missions. This project saw the creation of ultra-thin polymer-derived ceramics through the use of chemicals such as Aluminum Acetylacetonate, Dimethylformamide and Polycarbomethylsilane. These chemicals were mixed into several different homogenous solutions and applied onto different wafers located inside a spin coater. This spin coater evenly distributed each polymer solution across the wafer at varying RPMs. Once spinning and drying is finished, the polymers were then heat treated in a high-heat furnace to be made into a ceramic. At this point in the project, the Laser Induced Particle Impact Testing (LIPIT) machine is not finished, so formal testing of the materials cannot be completed, however once this happens, the results of which concentration and thickness of ceramic performed the best can be divulged. During this waiting period, other modifications to the experimental process can be made, such as the addition of Boron Nitride Nanotubes into the preceramic polymers for added strength.

Keywords: Preceramic Polymer, Nanomaterials, Spin Coating, Laser Induced Particle Impact Testing (LIPIT), Scanning Electron Microscope (SEM)