Research Symposium

25th annual Undergraduate Research Symposium, April 1, 2025

Isley Kellison Poster Session 4: 3:00 pm - 4:00 pm/ Poster #89

BIO

My name is Isley Kellison, and I am a sophomore studying biomedical engineering at FSU. I have a strong interest in organic chemistry, molecular biology, and cell and tissue engineering, which I plan to pursue in graduate school as I aim to establish a career in academia. My passion for art significantly enhances my research skills, whether through three-dimensional modeling and design, metal and glass work, or general illustration. My research incorporates these artistic abilities while allowing me to delve into my academic interests.

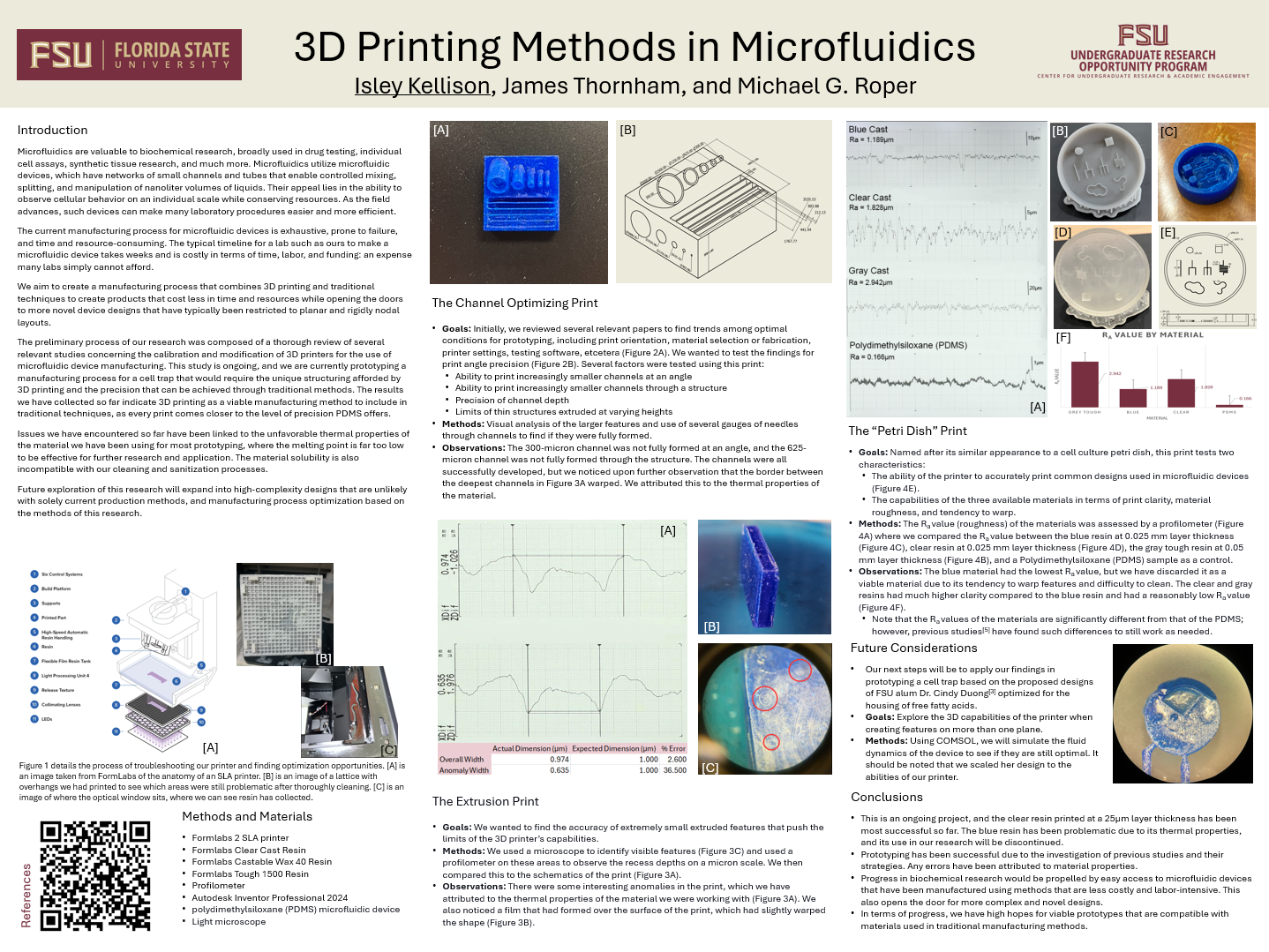

3D Printing Methods in Microfluidics

Authors: Isley Kellison, James ThornhamStudent Major: Biomedical Engineering

Mentor: James Thornham

Mentor's Department: Institute of Molecular Biophysics Mentor's College: College of Arts and Sciences Co-Presenters:

Abstract

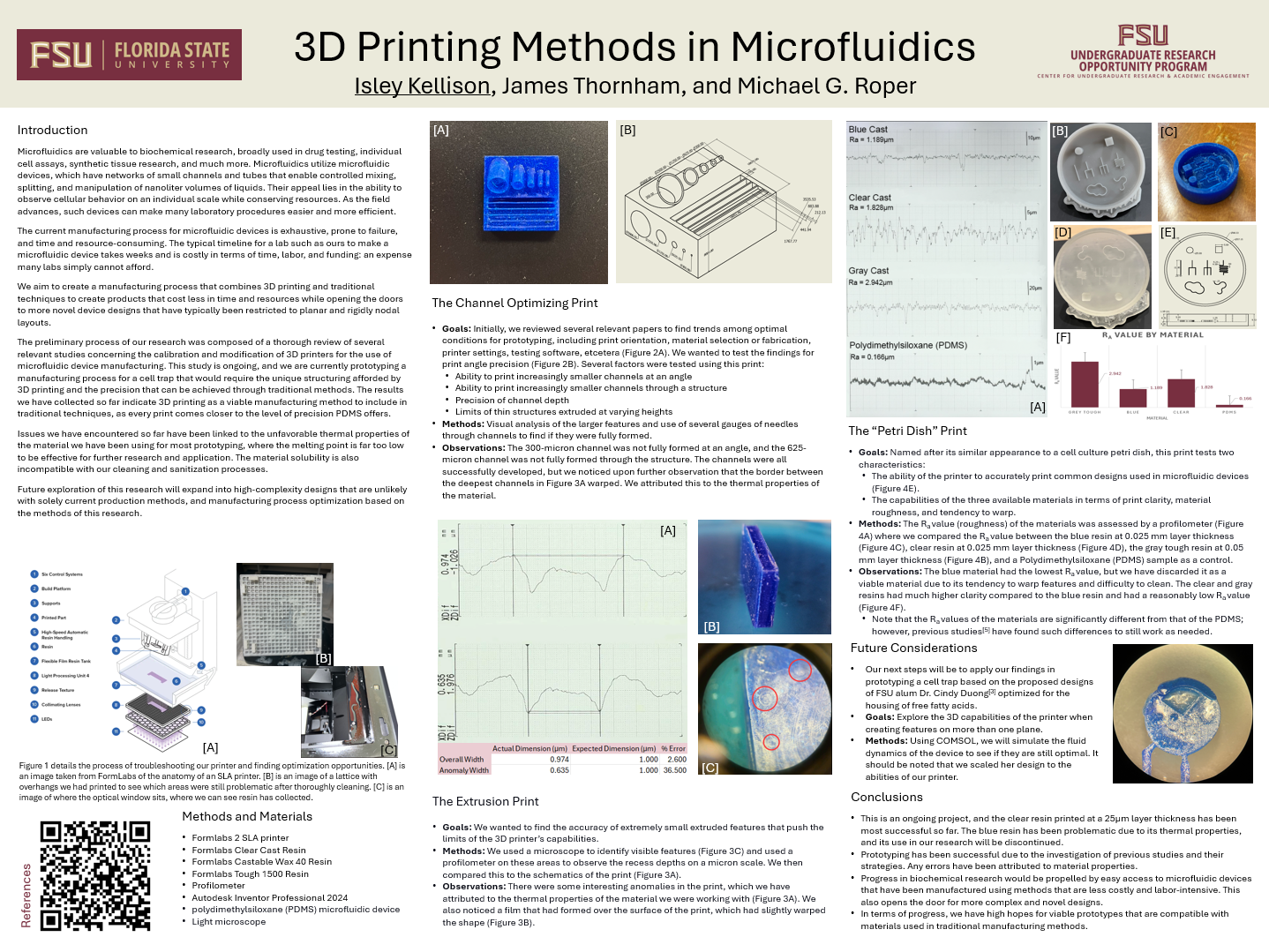

We aim to ease access to microfluidic devices through the utilization of both traditional and 3D printing methods in prototyping devices that may be difficult or too intensive to make otherwise. Microfluidics is the control of small volumes of liquids, typically using microfluidic devices. It is integral to biochemical research but is often too expensive to access due to its currently intense production process: 3D printing offers a solution that can democratize access and open the field to more novel designs than can currently be achieved. We conducted an analysis of several previous studies that used 3D printing methods, and based on this information, we designed several prototypes to calibrate the precision of our printer, which we’d measure with a profilometer and look to adjust our process based on texture errors we'd find in the print. After several successful prints of planar structures, we are looking to explore different materials and three-dimensional devices, starting with a cell trap. This project is ongoing, but the results we have gathered so far have been promising for the effectiveness of 3D printing as an alternative to purely traditional methods of production. Errors we have encountered have been attributed to the thermal properties and solubility of the material we have been using in testing and calibration. The implications of applying 3D printing techniques in the production of microfluidic devices could lead to the advent of more novel designs in an exploration of microfluidics in high-complexity systems without high risk of lost time and resources.

Keywords: Analytical Chemistry, 3D Printing, Fluid Dynamics, Chemical Engineering